Products

Products

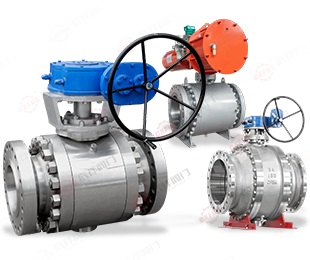

Overview:

A ball valve is a type of valve in which the opening and closing part (ball) is driven by the valve stem and rotates around the axis of the ball valve. It can also be used for the regulation and control of fluids. Among them, the hard-sealed V-type ball valve has a strong shearing force between its V-shaped ball core and the metal valve seat welded with hard alloy, making it particularly suitable for media containing fibers, tiny solid particles, etc.

Nominal diameter: 1/2" ~ 20" (DN15mm ~ 500mm)

Nominal pressure: 150LB ~ 1500LB/1.0MPa ~ 16.0MPa/10K ~ 160K

Manufacturing standards: GB, DIN, API, ANSI, JIS, BS, etc

Product material: WCB, A105, LCB, LF2, WC6, F11, WC9, CF8, F304, CF8M, F316, CF3, F304L, CF3M, F316L, CF8C, 4A, F51, 5A, F53, Inconel, Monel, 2205, 2507, 904L, copper alloy Titanium alloys, Hastelloy alloys, nickel alloys, etc

Drive methods: manual, worm gear, electric, pneumatic, hydraulic, etc

Overview:

A gate valve is a gate plate that opens and closes. The movement direction of the gate plate is perpendicular to the direction of the fluid. A gate valve can only be fully open or fully closed and cannot be used for regulation or throttling. Gate valves are sealed by the contact between the valve seat and the gate plate. Usually, the sealing surface is surfacing with metal materials to increase wear resistance, such as surfacing with 1Cr13, STL6, stainless steel, etc. Gate plates can be classified into rigid gate plates and elastic gate plates. Depending on the type of gate plate, gate valves are divided into rigid gate valves and elastic gate valves.

Nominal diameter: 1/2 "~60"

Nominal pressure: 150LB~1500LB

Manufacturing standards: GB, DIN, API, ANSI, JIS, BS, etc

Product material: WCB, A105, LCB, LF2, WC6, F11, WC9, CF8, F304, CF8M, F316, CF3, F304L, CF3M, F316L, CF8C, 4A, F51, 5A, F53, Inconel, Monel, 2205, 2507, 904L, copper alloy Titanium alloys, Hastelloy alloys, nickel alloys, etc

Drive methods: manual, worm gear, electric, pneumatic, hydraulic, etc

Overview:

The stop valve, also known as the gate valve, is a type of forced sealing valve and is one of the most widely used valves. It drives the valve disc to move linearly along the centerline of the valve seat through the valve stem, and relies on the pressure of the valve stem to make the sealing surface of the valve disc closely adhere to the sealing surface of the valve seat to achieve the function of preventing the flow of the medium. China's "Three Standardizations" for valves once stipulated that the flow direction of stop valves should uniformly be from top to bottom. In this way, under the action of medium pressure, the force required to close the valve is small and the force required to open it is large. The diameter of the valve stem can be correspondingly reduced, and at the same time, the valve is also more tight.

Nominal diameter: 1/2 "~60"

Nominal pressure: 150LB~1500LB

Manufacturing standards: GB, DIN, API, ANSI, JIS, BS, etc

Product material: WCB, A105, LCB, LF2, WC6, F11, WC9, CF8, F304, CF8M, F316, CF3, F304L, CF3M, F316L, CF8C, 4A, F51, 5A, F53, Inconel, Monel, 2205, 2507, 904L, copper alloy Titanium alloys, Hastelloy alloys, nickel alloys, etc

Drive methods: manual, worm gear, electric, pneumatic, hydraulic, etc

Overview:

A check valve is a type of valve with a circular disc as its opening and closing part, which operates by its own weight and the pressure of the medium to prevent the backflow of the medium. It belongs to the category of automatic valves, also known as check valves, one-way valves, backflow valves or isolation valves. Filters are indispensable devices on pipelines for transporting media, usually installed at the inlet end of pressure reducing valves, pressure relief valves, constant water level valves, and other equipment.

Nominal diameter: 1/2 "~60"

Nominal pressure: 150LB~1500LB

Manufacturing standards: GB, DIN, API, ANSI, JIS, BS, etc

Product material: WCB, A105, LCB, LF2, WC6, F11, WC9, CF8, F304, CF8M, F316, CF3, F304L, CF3M, F316L, CF8C, 4A, F51, 5A, F53, Inconel, Monel, 2205, 2507, 904L, copper alloy Titanium alloys, Hastelloy alloys, nickel alloys, etc

Drive methods: manual, worm gear, electric, pneumatic, hydraulic, etc

Overview:

Forged steel valves refer to valve devices that are suitable for use on pipelines of various systems in thermal power stations to cut off or connect the medium in the pipeline. Applicable media: water, steam and other non-corrosive media. The characteristics of forged steel valves compared with other valve products are high temperature and high pressure, as well as a unique self-sealing design. The higher the pressure, the more reliable the sealing. Due to the special performance and technical characteristics as well as the special working conditions, the product has formed features that cannot be replaced by other products.

Nominal diameter: 1/2 "~20" (DN15mm~500mm)

Nominal pressure: 150LB~1500LB/1.0MPa~16.0MPa/10K~160K

Manufacturing standards: GB, DIN, API, ANSI, JIS, BS, etc

Product material: WCB, A105, LCB, LF2, WC6, F11, WC9, CF8, F304, CF8M, F316, CF3, F304L, CF3M, F316L, CF8C, 4A, F51, 5A, F53, Inconel, Monel, 2205, 2507, 904L, copper alloy Titanium alloys, Hastelloy alloys, nickel alloys, etc

Drive methods: manual, worm gear, electric, pneumatic, hydraulic, etc

Overview:

Butterfly valves, also known as flap valves, are a type of simple-structured regulating valve that can be used for on-off control of low-pressure pipeline media. A butterfly valve refers to a type of valve where the closing member (disc or butterfly plate) is a circular disc that rotates around the valve shaft to achieve opening and closing. Valves can be used to control the flow of various types of fluids, including air, water, steam, various corrosive media, slurry, oil products, liquid metals and radioactive media. It mainly serves to cut off and throttle on pipelines. The opening and closing part of a butterfly valve is a disc-shaped butterfly plate that rotates around its own axis within the valve body, thereby achieving the purpose of opening, closing or regulating.

Nominal diameter: 1/2 "~60"

Nominal pressure: 150LB~1500LB

Manufacturing standards: GB, DIN, API, ANSI, JIS, BS, etc

Product material: WCB, A105, LCB, LF2, WC6, F11, WC9, CF8, F304, CF8M, F316, CF3, F304L, CF3M, F316L, CF8C, 4A, F51, 5A, F53, Inconel, Monel, 2205, 2507, 904L, copper alloy Titanium alloys, Hastelloy alloys, nickel alloys, etc

Drive methods: manual, worm gear, electric, pneumatic, hydraulic, etc